The First Production Brew

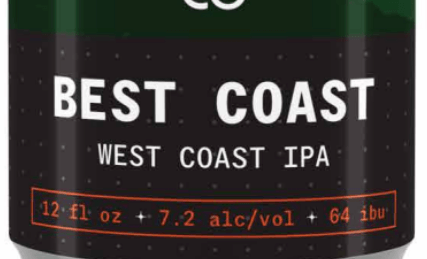

Lost Nomad Brewing Company hit an important milestone in January 2024 with the first production brew of one of our launch beers: the Best Coast West Coast IPA! As a contract brewer, we’re thrilled to partner with City-State Brewing in Washington, D.C. to get the product to a wider audience and start receiving more feedback on both the product and the concept. Like we mentioned a year ago, we also need to register the use of our core trademarks (meaning the marks core to the concept of the brewery, not individual fanciful names of beers). There were, and are, a fair amount of unknowns in getting our beers produced and distributed in a way that makes sense longterm, but we’re excited how far we’ve come in the last 12 months.

Note: for those local to Washington, D.C. who want to get their hands on our first batch of beer as it comes off the canning line, we’ll send a separate note soon about an event on March 1st. If you’re receiving this newsletter, you’ll get that message as well.

Bring Your Kid to Brew Day

I’ve never participated in a brew day on a production-scale system. Needless to say, I woke up that day like a kid on Christmas morning. I met up with the master brewer, Greg, and we got to work. Knowing that labor is expensive and hard to come by, I wasn’t worried about getting in the way or being an unwelcome addition to the brew house. Rather, we ended up exchanging notes about our processes and differences in brewing (primarily around efficiencies) at a ten barrel scale.

Quite literally an adult-child in a brewery

It turns out there aren’t a lot of differences in the processes and my own recipes are simple enough that there wasn’t a lot of modification required. My original concept of Beer Lab started around the idea of streamlining logistics and varying recipes with just one ingredient to create entirely different beers, so there wasn’t a lot of fat to trim from my small scale recipe. The obvious differences at scale are the type of equipment: double-walled, steam-heated brew houses and double-walled, glycol chilled fermenters are commonplace in production facilities. Brew houses below one barrel are stuck with direct-heating elements and glycol-chilled immersion coils (basically things that make cleaning a more painful experience).

After taking notes all day and literally chatting with Greg for twelve hours as we brewed, we pitched our yeast in the fermenter and I walked away with a list of things to bring back to my own brew house. I have several things, most of which were pretty surprising, to try in the coming months:

- Pitching an enzyme called ALDC reduces diacetyl in the beer and saves time by eliminating the need for a diacetyl rest after primary fermentation

- Testing water salt additions to the primary to lower the pH (like Gypsum) beyond what’s needed for conversion in the mash tun

- Lowering my whirlpool time to only a few minutes, meaning get the wort turning but then shut off the pump and perform any hopstand

- Blowing the dust off my pro-series in-line oxygen system. I’ve been meaning to do this for a while but I didn’t have the correct threads for European gas tanks

- Harvesting yeast from the bottom of the fermenter (I know, I know I should already be doing this but I’ve just been overbuilding my yeast starters and harvesting from there)

- Eliminating the addition of oxygen to the primary fermenter when using dry yeast (which seems like witchcraft to me)

Overall, I was able to follow along what part of the process we were at despite needing help operating some of the automated components of the brew system. It was an eye-opening experience and it still amazes me the degree to which experience can influence quality in a brew house regardless of the equipment installed there. That might seem like an obvious conclusion but there really isn’t any autopilot button and, particularly at large scales, the brewer needs to understand the “why” for every part of their system and process. It makes me appreciate a good beer on a whole new level.

Wild Yeast: Continued

During my trip back to the U.S. for the contract brew, I brought a sample of locally captured wild yeast with me to get analyzed by a local yeast lab. The idea is to use this yeast in an upcoming batch of beer; that is, if a few things align: it needs to be allowed by the brewer, actually be some kind of beer yeast that’s desirable, and not be some microbe that causes The Last of Us to happen.

Hand-carried from a fruit tree in West Africa

Fast forward a few weeks and the yeast analysis and isolation are complete. What I gave the lab in my hand-carried vial (and presumably brewed with previously) was a mix of bacteria and yeast strains. They ran a few tests and can confidently say the bacteria is either Lactobacillus or Pediococcus (which I’d be more excited about if I were trying to make a sour). There were also two yeasts present, one of which is a type of Saccharomyces cerevisiae (ale yeast) and the other was inconclusive (meaning it could be an ale or lager yeast).

The amazing crew at Jasper Yeast Lab

What I didn’t know about until going through this process is that there is a particular gene present in some yeasts called STA1 (which technically is a yeast called Saccharomyces cerevisiae var. diastaticus). The long and short of it is that this gene is both good and bad depending on what your objectives are as a brewer. Some brewers, like Greg, won’t allow it in their brew house given it can lead to consequences downstream (like over-carbonating in packaging) and it’s difficult to decontaminate the brewery once it’s introduced. Luckily, my strain is STA1 negative but it was fascinating to learn about this aspect of yeast. We’re still in the process of identifying exactly what strain of yeast we’ve wrangled, and we’re still working on whether or not we can use this in an upcoming production batch of the West African Coast IPA, so stay tuned about that.

What’s Next

I stayed with a friend during my trip back to the U.S. and what occurred to me is that the phrase "Exploration Through Fermentation" can apply beyond beer (okay, not according to the USPTO). This friend is deep into making bagels and at the beginning of his own journey of turning that into a business. What I didn’t know is that one step of the bagel-making process is to boil the fermented and shaped bagel dough in beer wort prior to baking. That was enough for me to want to collaborate in the future on something bagel related–to the extent that I’m now making bagels using my dry malt extract at home. I also purchased a cold brew coffee system in an attempt to attract customers who are remote workers to open their laptops in my taproom (a concept becoming more popular in U.S. breweries post-pandemic).

Maybe I should boil bagels in the kettle on every brew day

We’ll be back in the U.S. again this month to can the Best Coast IPA but we’re also attending a three day yeast workshop/lab in Asheville, NC as well. I’m personally excited to learn more about yeast quality control and lab practices at scale, and I’m also bringing some open questions with me from my brew day with dad Greg. As an aside, I did get accepted to the annual UC Davis Master Brewer program, but given a number of factors I need to defer attendance to next year. The yeast workshop will have to suffice for now.

We’re only in the second month of this year and things are progressing nicely. Once we’ve got our production and distribution processes in place, we’re excited to use the Lost Nomad tap room to create recipes that we then pass over to the larger production facility. It’s an exciting time for the brewery and we hope our Local Nomads, both here in West Africa and in D.C., enjoy the beers because we brewed them for you.